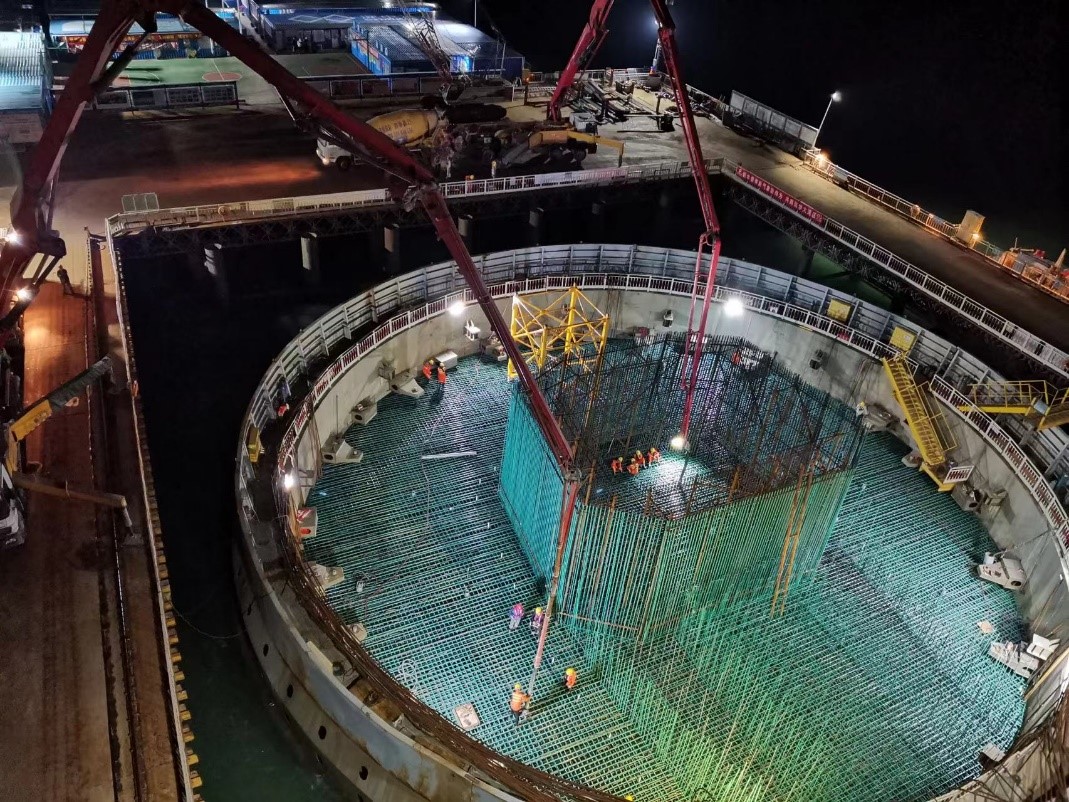

Concrete pouring epoxy rebar.

On July 1, The Paper learned that the Ningbo Institute of Materials Technology and Engineering of the Chinese Academy of Sciences has developed new materials to provide a century of durable protection for the Shenzhen-Zhongshan Link project.

The Shenzhen-Zhongshan cross-river channel (referred to as "Shenzhen-Zhongshan Channel"), which took 7 years to build, was officially opened to traffic for trial operation on June 30, 2024.

The Shenzhen-Zhongshan Channel is one of the most difficult cross-sea cluster projects in the world to build, facing challenges such as typhoons, harsh environments with high salt and humidity, and complex seabed conditions.

However, there are gaps or voids in the reinforced concrete of marine engineering facilities, which will cause steel corrosion when eroded by salt water or acid rain. Its steel casing faces extremely serious damage problems in the coupled damage environment of high temperature and salt, saturated oxygen, strong ultraviolet rays, humid sea breeze, wave slapping and sediment erosion in the coastal environment. Therefore, the stability of the performance of steel bars and steel casings is directly related to the service life of marine engineering facilities.

Shenzhen-Zhongshan Bridge.

The Shenzhen-Zhongshan Link, a core hub project in the Guangdong-Hong Kong-Macao Greater Bay Area, integrates "bridges, islands, tunnels, and underwater interconnections" and is approximately 24 kilometers long.

With the support of the National Key R&D Program, Ningbo Science and Technology Innovation 2025 Major Project and Ningbo's "13th Five-Year Plan" Marine Economic Innovation and Development Demonstration Project, Academician Xue Qunki and Researcher Wang Liping from the National Key Laboratory of Marine Critical Materials of the Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, led the Harsh Environment Materials Coupled Damage and Life Extension Team, and jointly with Ningbo Kexin Corrosion Control Engineering Co., Ltd., developed a two-dimensional nanomaterial-reinforced high-durability fusion-bonded epoxy-coated steel bar technology, changing traditional passive maintenance to active prevention.

The steel casing, abutments and pier structures of the Shenzhen-Zhongshan Bridge use highly durable fusion-bonded epoxy anti-corrosion coatings and epoxy steel reinforcement materials, which greatly improve the corrosion resistance and wear resistance of the related structures, providing the Shenzhen-Zhongshan Channel project with a comprehensive protection solution that can meet a service life of 100 years.

Experts said that the coating has excellent adhesion, and the two-dimensional material further improves the physical barrier properties of epoxy resin. Therefore, the coating has an excellent " maze effect " on corrosive media, thus obtaining good corrosion resistance.

Among them, epoxy steel bar coating has small drying shrinkage, large ductility, excellent bendability, coating adhesion and bonding strength, and can effectively resist the corrosion of steel bars by deicing agents, salt, seawater, acid rain, chemicals and concrete additives, greatly extending the corrosion resistance life of steel bars.

The integrated manufacturing technology of large-size high-strength steel casing and its high-durability protective coating on its surface has the advantages of good corrosion resistance and durability, and a thermal expansion coefficient similar to that of concrete. It meets the major development needs of modern marine engineering structures towards large size, heavy load, high strength and working under harsh conditions, and solves engineering and technical problems such as preventing hole collapse and avoiding affecting construction progress.