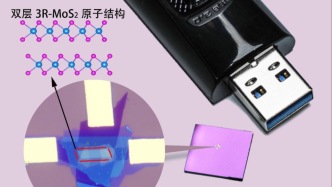

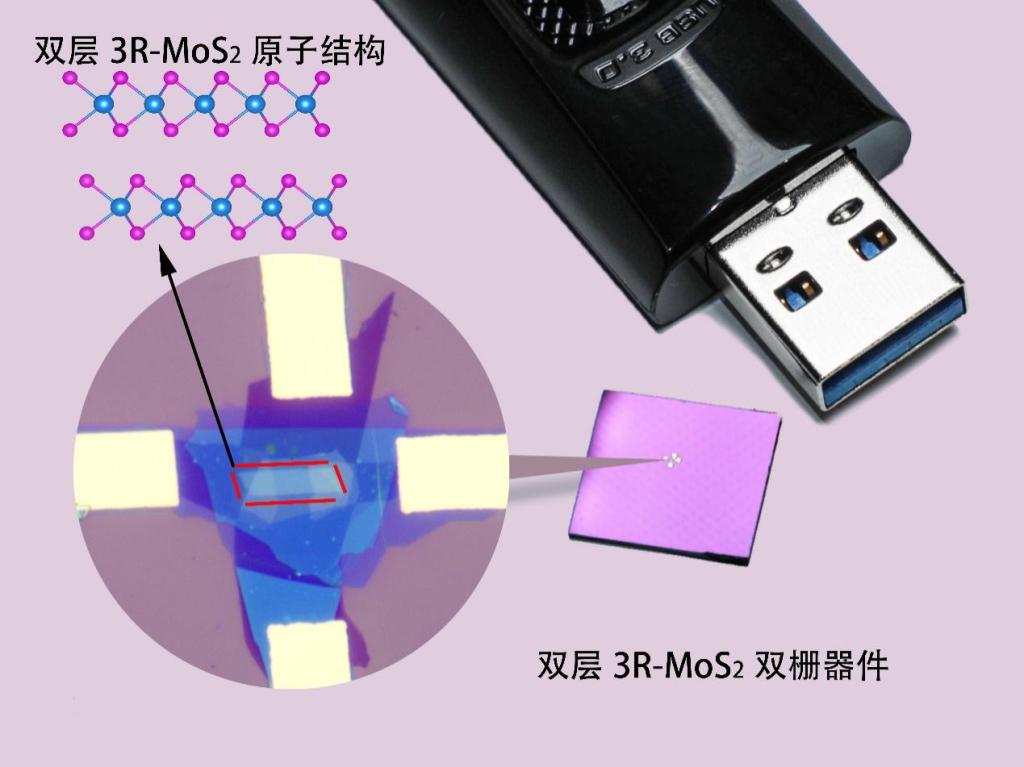

Field effect transistor device based on double-layer MoS2 slip ferroelectric material.

Crystalline materials are not necessarily perfect, but may contain a large number of defects. A deep understanding of the various " behaviors " of material defects can help scientists develop "fatigue-resistant" materials.

Although ferroelectric materials have "iron" in their name, they actually have nothing to do with the metal "iron". "Ferroelectric" here refers to an insulating material. Under the action of an external electric field, its charges can be rearranged to produce electric polarization. Even if the electric field is removed, the arranged charges can still remain in their original state, that is, they have a memory function.

Ferroelectric materials, like the materials on common cassette tapes more than a decade ago, can be used as non-volatile memory, with the advantages of low power consumption, lossless reading and fast repeated writing.

Ferroelectric materials are currently widely used in electronic devices such as memory, piezoelectric elements, and sensing devices.

However, traditional ferroelectric materials will produce fatigue: as the number of polarization reversals increases, the polarization of the ferroelectric material will decrease, causing its performance to degrade and eventually leading to device failure.

Globally, fatigue failure of ferroelectric materials is one of the main causes of failure in various electronic devices.

To address the above issues, the Flexible Magnetoelectric Functional Materials and Devices Team of the Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, in collaboration with relevant teams from the University of Electronic Science and Technology of China and Fudan University, started from the microscopic principles of ferroelectric fatigue and used the uniqueness of the two-dimensional slip ferroelectric structure to create a fatigue-free ferroelectric material.

This application is expected to break the limitation of the limited read and write times of ferroelectric memory and greatly increase durability, so that it can perform key tasks such as storage, sensing, energy conversion, etc. in deep-sea exploration, aerospace, and flexible wearable electronic devices.

In the early morning of June 7th, Beijing time, the above research results were published online in the international academic journal Science.

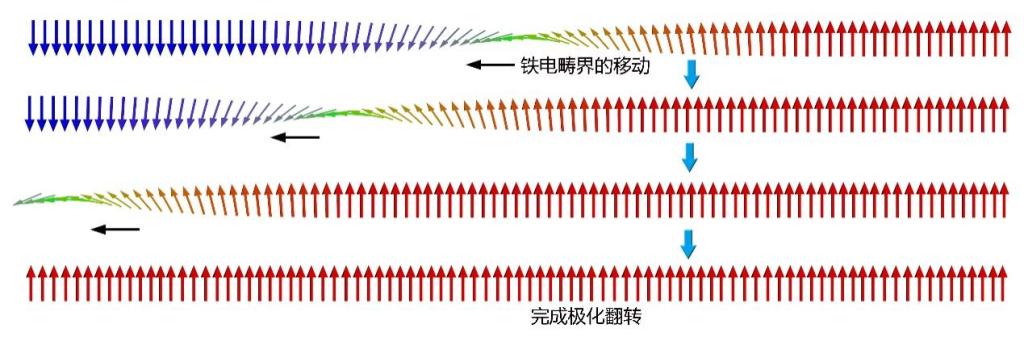

Schematic diagram of the polarization reversal process.

Traditional ferroelectric materials have countless lattice units inside, and charged ions are gathered in each lattice unit. These charged ions will move under the action of the electric field, resulting in polarization reversal.

The research team found that there are many defects inside the crystals of traditional ferroelectric materials. More importantly, these defects will aggregate during the propagation of "polarization reversal" and become defect clusters, thereby hindering the normal "polarization reversal", causing polarization fatigue in the material and irreversible damage to the device.

The process of a small defect gathering into a "defect cluster" is like the process of small stones accumulating into a large reef that cannot be ignored.

How to avoid the formation of "defect clusters"?

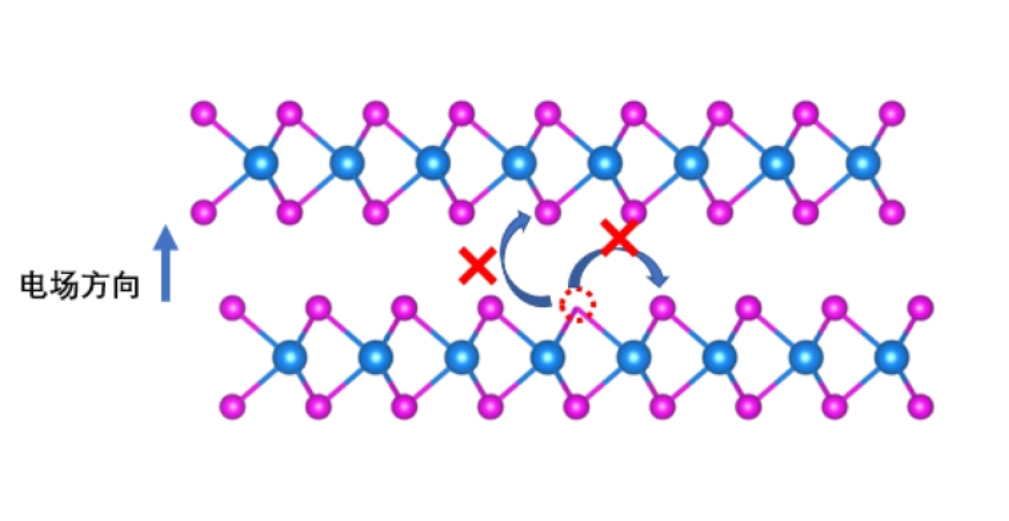

The solution finally adopted by the research team is not to eliminate the defects in these crystals, but to prevent these "defects" from moving and gathering. But at the same time, it cannot affect the occurrence and propagation of "polarization reversal".

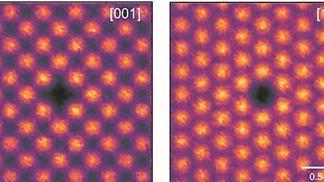

They thought of two-dimensional layered slip ferroelectric materials, using "interlayer slip" to replace the "ion movement" of traditional ferroelectric materials. Under the action of the electric field, slip will occur between the layers, and charge transfer will occur between the layers, resulting in polarization reversal.

The research team first demonstrated through theoretical calculations that since there is no need to overcome the covalent bonds between ions, the external electric field required for polarization reversal is small and not enough to move the defects. In addition, due to the two-dimensional layered structure, it is difficult for defects to move across layers, so the defects will not aggregate and will not produce ferroelectric fatigue.

In conventional ionic ferroelectric materials, under the action of an electric field, the polarization reversal of each lattice unit in the ferroelectric material does not occur simultaneously, but propagates from one end of the material to the other like a wave. During the propagation process, defects in the material move and gather.

The principle of the new material's anti-fatigue effect is that there is a van der Waals gap between layers, like a wall that isolates the defects and prevents them from moving; inside the layers, the defects are also unable to move due to the lack of a transverse electric field.

The research team used double-layer molybdenum disulfide as a representative material and prepared a double-layer molybdenum disulfide ferroelectric device through the chemical vapor transport (CVT) method, the thickness of which is only at the nanometer level. The study found that after millions of cycles of electric field reversal polarization, electrical curve measurements showed that the ferroelectric polarization did not decay, and the fatigue resistance was significantly better than that of traditional ionic ferroelectric materials. This means that the memory using the new two-dimensional layered slip ferroelectric material not only has basically no limit on the number of reads and writes, but the ultra-thin thickness can also greatly improve its storage density. Therefore, for deep-sea exploration or major aerospace equipment, the new fatigue-free two-dimensional layered slip ferroelectric material can greatly improve equipment reliability and reduce maintenance costs.

In the review, one reviewer said, "It is very clever to solve the ferroelectric fatigue problem through the slip ferroelectric mechanism." Another reviewer said, "The authors have demonstrated a way to solve the well-known performance degradation of traditional ferroelectric materials. Obviously, the barrier to polarization reversal in slip ferroelectrics is much smaller than the barrier to defect migration, which has been successfully revealed."

He Ri is an associate researcher at the Ningbo Institute of Materials, Chinese Academy of Sciences.

Associate Researcher He Ri from Ningbo Institute of Materials is the co-first author of the above-mentioned latest published paper, and Ningbo Institute of Materials is the co-corresponding unit. This work was supported by the National Natural Science Foundation of China and the Zhejiang Provincial Natural Science Foundation.