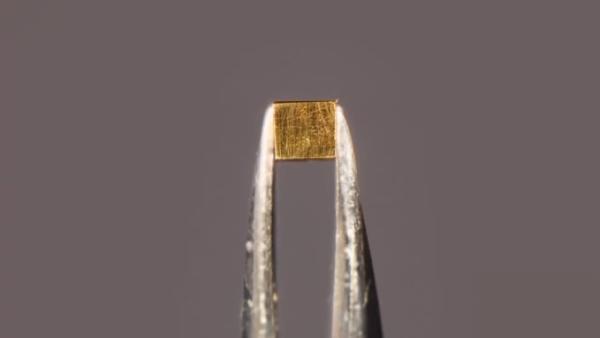

After long-term research, the research team of the Institute of Metal Research, Chinese Academy of Sciences , has achieved the goal of reducing material density and significantly improving material strength without losing or even improving plasticity by dispersing holes with diameters of less than 100 nanometers in the material. This achievement was published online today (9th) in the international academic journal Science.

At present, lightweighting of metal materials is generally achieved by adding lighter elements such as aluminum and lithium to the metal . A team from the Institute of Metal Research, Chinese Academy of Sciences, found that compared with conventional methods, the introduction of nanopores is a more intuitive, effective and cleaner way to reduce the weight of materials . However, in general, the presence of a small number of holes will lead to a sharp decrease in the mechanical properties of the material, such as strength, plasticity and toughness. After a long period of research, the scientific research team successfully broke through this difficulty by adding dispersed nanopores with a diameter of about 100 nanometers or even smaller to the material, thereby reducing the material density and greatly improving its strength without losing or even improving plasticity.

Experimental data show that the yield strength of the new material after the introduction of nanopores has increased by 50% to 100%, which means it has a higher load-bearing capacity . This new strengthening method not only helps to make the material lightweight and recyclable, but also retains the excellent physical properties of the original material, such as thermal conductivity and electrical conductivity, to a greater extent. It is expected to be applied in many fields such as aerospace in the future.