The surface of the very large crude carrier (VLCC) propeller is covered with an artificial material similar to dolphin skin - bionic skin.

On July 8, The Paper learned from the Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences (Ningbo Institute of Materials) that the institute's research team has artificially prepared an artificial material with characteristics similar to dolphin skin - bionic skin, which can transform the sliding friction between water flow and the skin into rolling friction. At the same time, it can also reduce the shear force between water and the skin. It has been laid on the surface of very large crude tankers (VLCC) propellers and achieved good energy-saving and emission reduction effects.

Recently, the first 300,000-ton ultra-large oil tanker equipped with a bionic skin propeller successfully berthed at the Quanzhou Port Terminal, completing three voyages of crude oil transportation missions.

This is the first time in the world that bionic flexible drag-reducing materials have been applied to 300,000-ton ultra-large oil tankers, completing the collection of energy-saving data over multiple voyages, long voyages, and multiple sea areas.

Data shows that after the propeller surface is covered with bionic skin, the fuel consumption of the actual ship drops by about 2%. Based on this calculation, a super-large oil tanker can save more than 300 tons of fuel per year, which is equivalent to directly increasing economic benefits by more than 1 million yuan and reducing carbon dioxide emissions by more than 900 tons.

According to data from the International Energy Agency (IEA), the energy consumption of the shipping industry accounts for about 9% of the total global energy consumption, and the carbon dioxide emissions account for 3% of the total global carbon dioxide emissions. Therefore, breaking through the key technologies of energy conservation and emission reduction of large ships and leading the green transformation of the global marine transportation industry are of great significance to the country's realization of the "dual carbon" goal.

"Marine bionic skin drag reduction and energy saving technology" is a scientific research project jointly carried out by the Key Laboratory of Marine Key Materials of Ningbo Institute of Materials and China COSCO SHIPPING Energy Co., Ltd. (hereinafter referred to as COSCO SHIPPING Energy).

Under the planning of Xue Qunki, an academician of the Chinese Academy of Engineering and researcher at Ningbo Institute of Materials, researchers Wang Liping and Zeng Zhixiang from the Key Laboratory of Marine Key Materials of Ningbo Institute of Materials led the research team to carry out research on surface bionic sliding materials and drag reduction of marine vehicles at an early stage.

When a marine engine drives a propeller to rotate, about 70% of the energy consumed is converted into thrust, about 15% is consumed by the propeller shear force doing work on the water, and the remaining about 15% is consumed by the propeller reverse thrust doing work on the water.

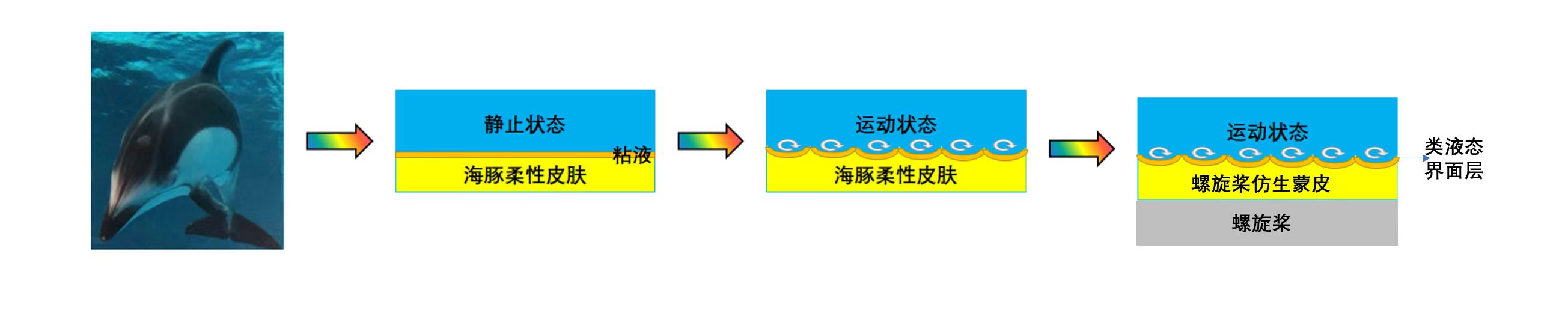

Dolphins, sharks and other marine creatures have extremely low resistance when swimming in the sea, mainly due to their surface microstructure, flexibility and surface mucus secretion characteristics.

Artificial bionic drag-reducing materials can easily achieve the microstructure and flexibility of the dolphin's epidermis, but it is relatively difficult to imitate the long-term mucus secretion of the dolphin's epidermis. "Liquid-like" materials effectively solve this problem.

Highly flexible molecular brushes grafted inside solid organic molecules can not only maintain the strength of the solid material but also achieve slip characteristics similar to "mucus", and are called "liquid-like" materials.

Schematic diagram of dolphin skin and propeller bionic skin.

The bionic skin is made of a dynamic interface material with "liquid-like" characteristics coupled with a flexible material with a microstructure of 0.1-0.2 mm in size. It is laid on the surface of the propeller and can reduce the shear force between the propeller and the water, and reduce the work done by the reverse thrust on the water, thereby improving the propeller efficiency and reducing energy consumption.

COSCO SHIPPING Energy is working closely with Ningbo Institute of Materials to promote the aforementioned drag reduction materials to COSCO SHIPPING Energy's fleet of more than 100 tankers. In the future, marine bionic flexible drag reduction materials will be promoted and applied to the entire industry, including ocean and inland river transportation.